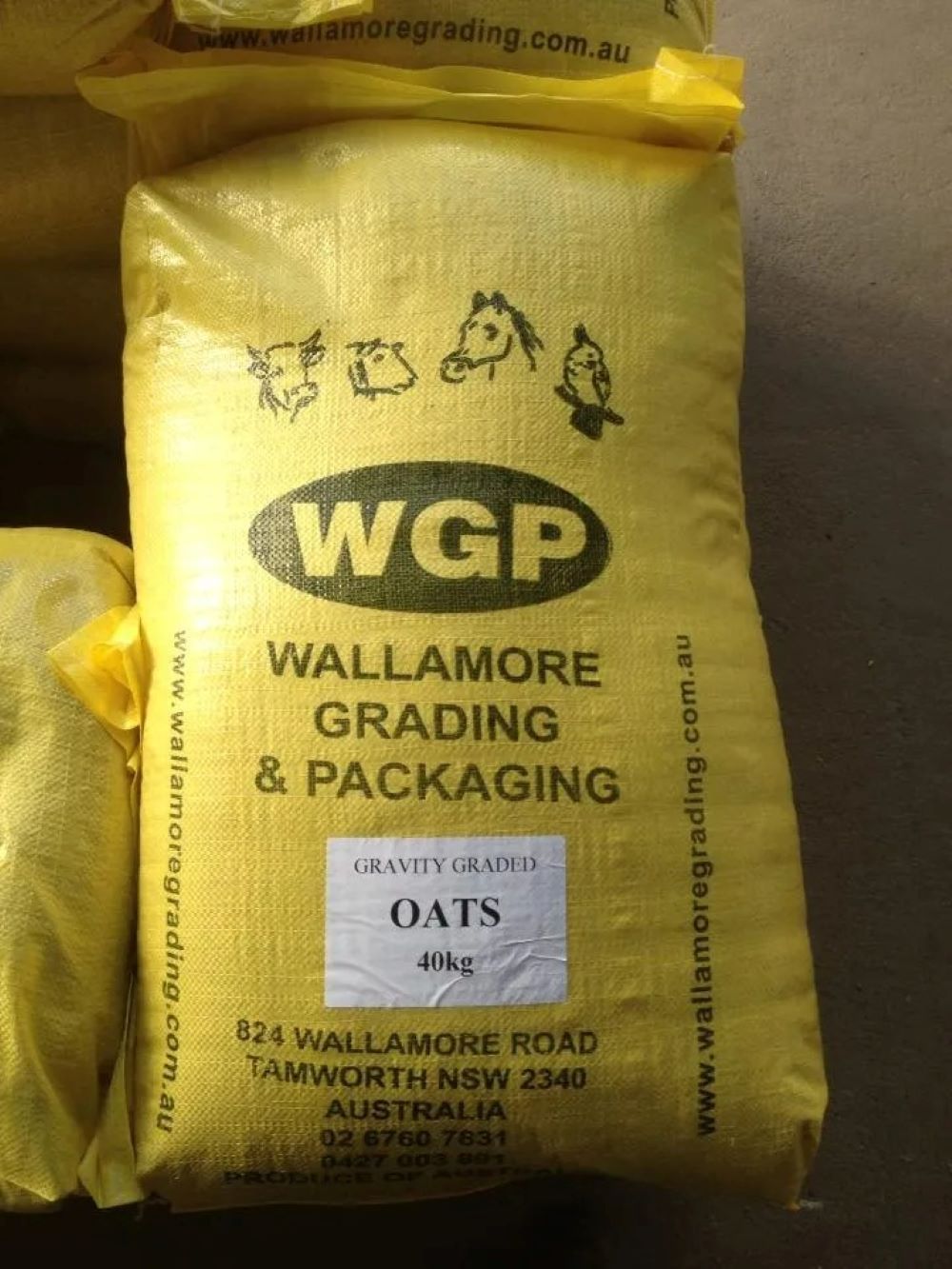

Wallamore Grading & Packaging

Seed Cleaning in Tamworth

- Supporting regional agricultural communities

- Reliable service backed by experience

- Supplying quality products

Tamworth Seed Cleaning & Grading

Do you want to maximise the profits earned on your next crop? Need your grains or seeds mixed? For the very best in seed cleaning and mixing services, Wallamore Grading & Packaging is the seed processing plant you can rely on!

Based in Tamworth, we use high-capacity gravity grading equipment which enables us to grade and clean almost all varieties of oil, grain and grass seed. Our automated bagging system can then separate your produce into the amounts you require with precision.

What’s more, we also offer a mixing service, with the ability to mix up to five tonnes of grains and seeds for all your harvest or livestock grazing requirements. Whatever your needs, just let us know and we’ll be happy to help! For more information, give our friendly team a call on

02 6760 7831.

Wholesale Pricing

Quality Equipment

Hands-On Knowledge

Timely Service

Cleaning & Grading Made Easy

At Wallamore Grading & Packaging, we grade a range of seeds for our customers. Some of the most common seed varieties we process include:

- Staple cereal grains such as oats, wheat, barley, corn, canary & millet

- Flowering plant grains such as sorghum, chicory, canola, linseed & sunflowers

- Legume crops such as chickpeas, soybeans, cowpeas, lupin & lucerne

We also process varieties of grass seed including:

- Rye Grass

- Vetch

- Clover

- Phalaris

Our team can bag up your seed into volumes of 20kg, 40kg, one tonne, or by bulk truck load. We can also organise non-standard sizes upon request. Whatever you’re after, let us know and we’ll do our best to meet your requirements.

Frequently Asked Questions

Can I reuse seed from last year without cleaning it?

Reusing seed without cleaning can lead to lower germination rates and the spread of weeds or disease. Uncleaned seed may also contain debris, insect damage or moisture issues that affect storage and planting. Cleaning removes these contaminants and ensures only viable seed is sown. While it’s possible to reuse seed, cleaning it first improves quality, crop performance and reduces risks in the following season.

How does seed grading improve planter performance?

Grading creates uniformity in seed size and weight, which helps mechanical planters distribute seed more evenly. Uneven seed sizes can cause skips or clumping during sowing, resulting in inconsistent crop emergence. With properly graded seed, farmers benefit from better seed placement, faster planting speeds and less wear on equipment. This translates to improved efficiency and stronger overall crop establishment in the field.

What contaminants are removed during seed cleaning?

Seed cleaning removes various contaminants, including dust, chaff, dirt, weed seeds, broken seed, insects and mould fragments. These contaminants can reduce germination, spread disease or cause storage issues. The cleaning process uses screens, airflow and separation equipment to remove unwanted material while preserving viable seed. Cleaner seed is more marketable, easier to store and safer to plant or sell.